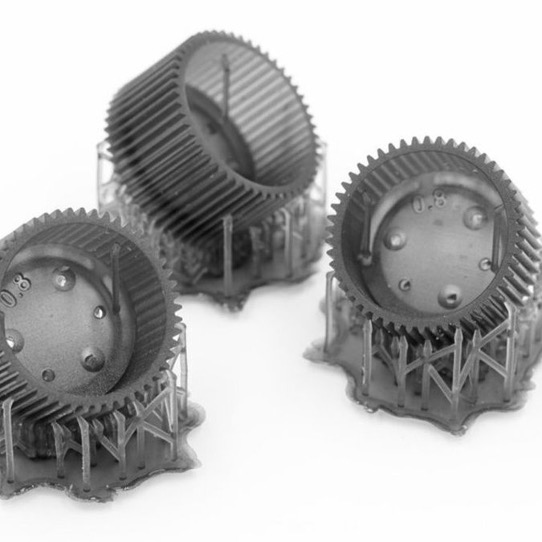

SLA is a 3D printing process that dimensionally settles the curing of a photoactive liquid resin. The SLA process uses a scanning laser causing a chemical reaction that converts it into a crosslinked solid.

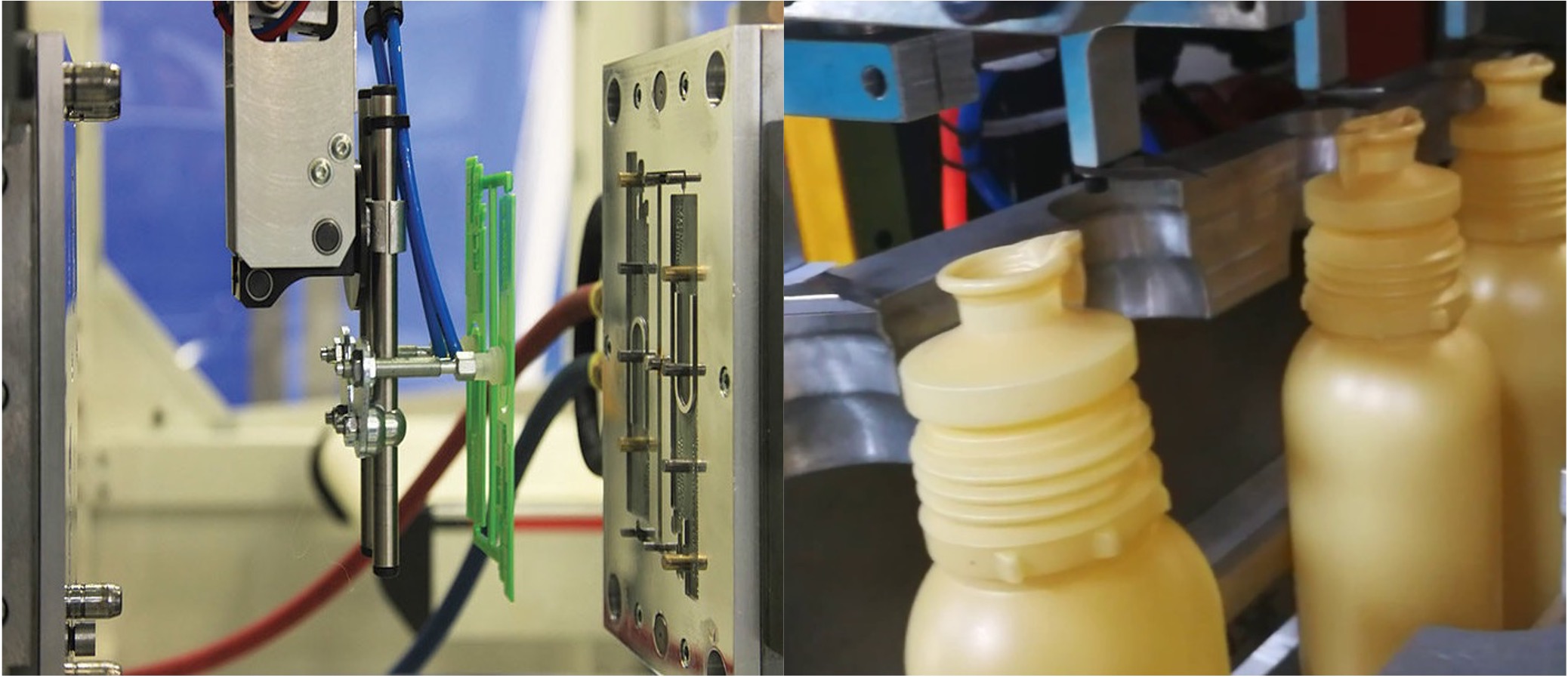

SLA 3D printer could print very high surface quality parts resembling that of injection molding with all the small features are visible. Resolution quality depends upon the SLA printer specification like laser spot size and resin quality.

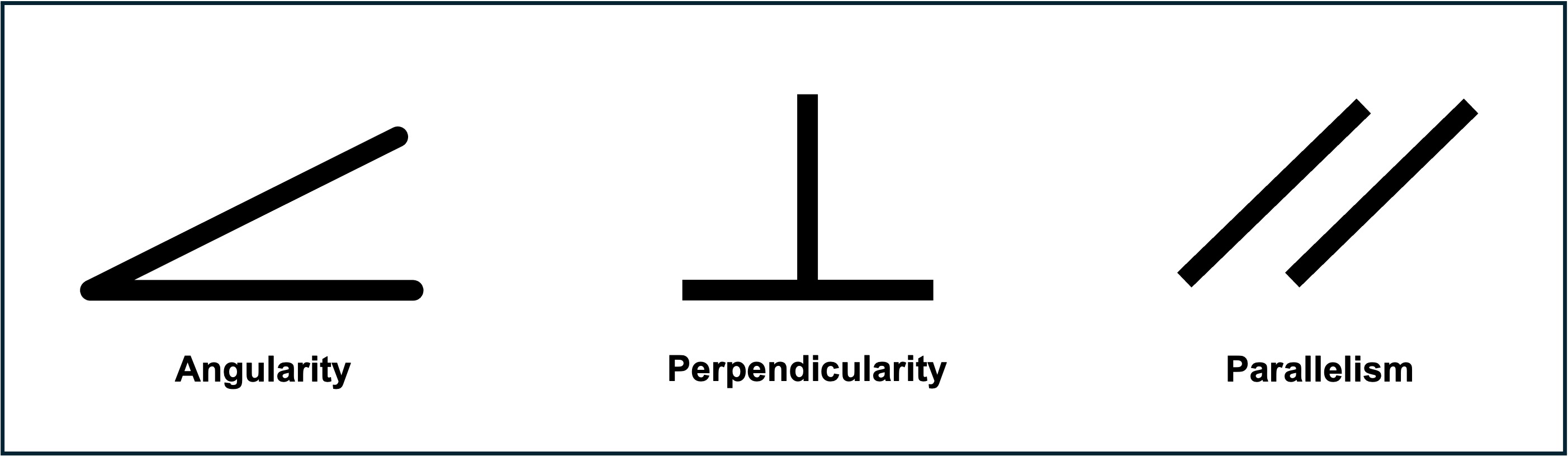

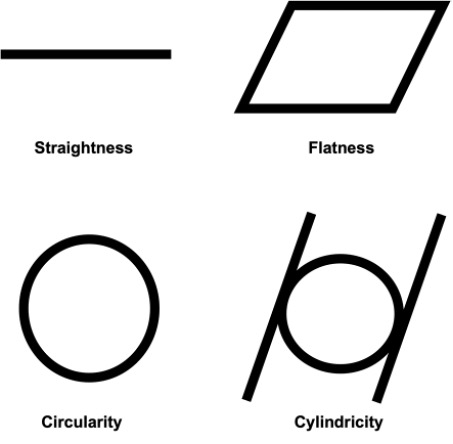

Below are design guidelines generally applied for the SLA 3D printing process. These guidelines will help the designer to create parts that will result in a successful print.

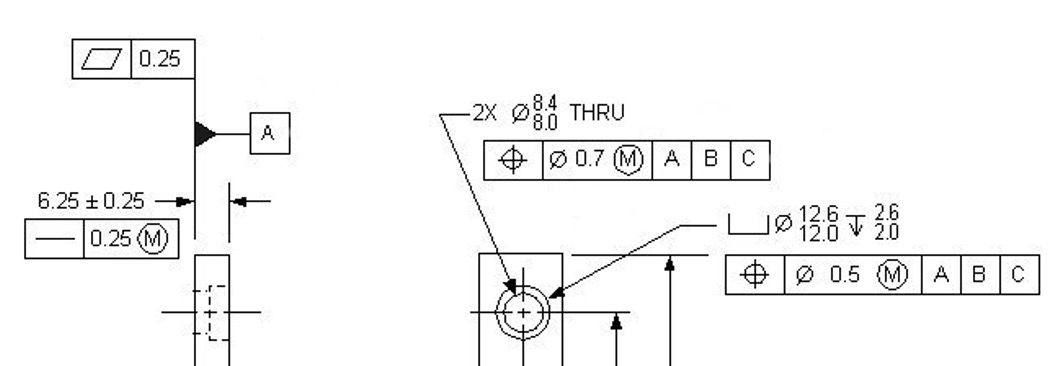

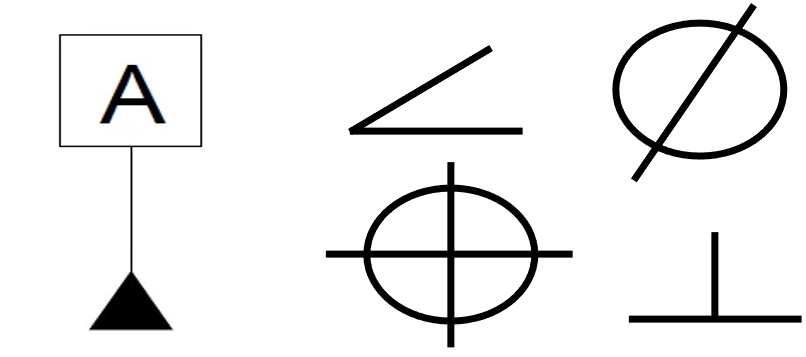

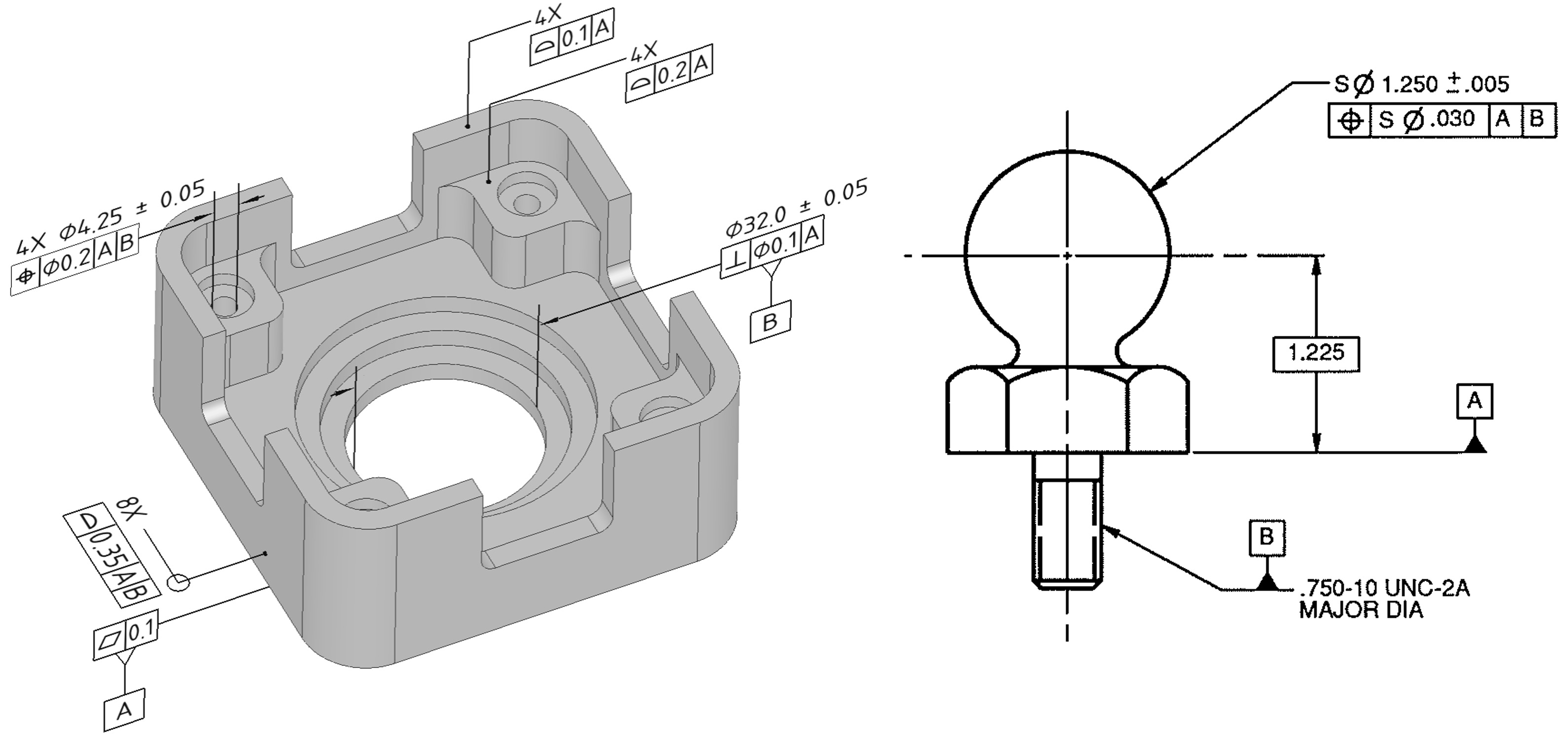

Minimum supported wall thickness

Walls with supports are joined with other walls or shape at least two sides. Minimum thickens of 0.4 mm is recommended.

Minimum unsupported wall thickness

Without support, walls are joined with other walls on less than two sides. A wall without support that is smaller than 0.6 mm may warp or break from the model during printing.

Maximum unsupported overhang length

An overhang refers to a part of the model that extends outwards over horizontally parallel to the build platform. Printing such features without supports are not advised, as the layers cannot maintain their structure. Unsupported horizontal overhangs will be slightly deformed beyond 1 mm and become increasingly deformed as the length of the overhang increases

Minimum angle to avoid support

Design feature/surface can self support up to ∠19° of angle. Angle falling below 19° need supports to generate surfaces.

Maximum horizontal un-supported span

It is recommended to keep unsupported bridges within 20mm of length for a 5mm wide & 3mm thick bridge. Wider beams must be kept shorter to avoid breaking during the peeling process.

Pin diameter

0.3 mm thick wire can be printed up to 7mm before any defect. 1.5 mm wires can get up to 30 mm tall without any failure.

Clearance for connecting & moving parts

0.5mm clearance for any mating/sliding parts

0.2mm clearance for assemblies

0.1mm clearance for push fitting

Embossing & engraving

Embossed details are small raised features on your design. Details smaller than 0.2 mm in thickness and 0.2mm in height may not be visible on your print.

Engraving is the practice of incising a design onto a surface either flat or curved. The minimum recommended depth and width of 0.4mm should me maintained.

Holes

The Minimum recommended hole diameter is 0.5 mm.

Size below 0.5mm may not appear.

Tolerance

Industrial SLA printing has a dimensional tolerance of ± 0.15% and a lower limit of ± 0.01 mm.

DfAM for SLA

3D SculpLab

3D SculpLab