- 34 materials

- Lead time from 2-3 weeks

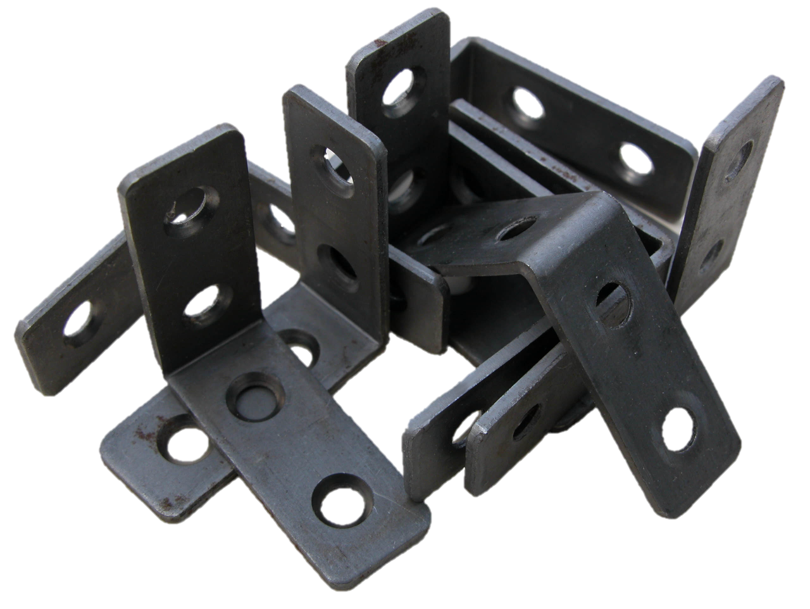

Prototype And Low Volume Production

See more

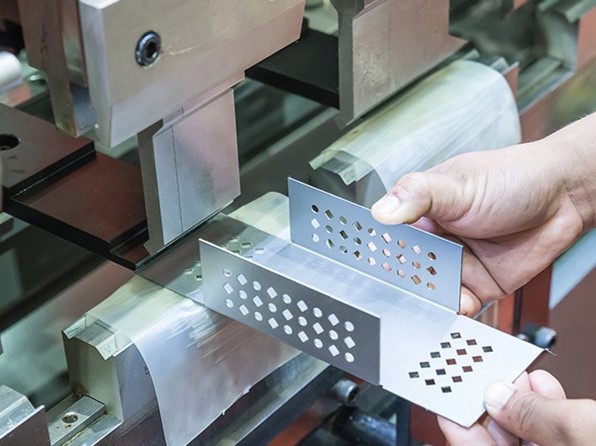

Laser cutting | Bending

Get a quick quote

Materials

Get parts in 5~10 working days

Upload Cad

Select Material

Select Finish

We Make it

Get your parts

| Surface Finish | Image | Remark |

|---|---|---|

| As machined (Ra 3.2 µm) |  |

|

| Brushed (Ra1.2µm) |  |

|

| Powder coated |  |

|

| Satin finish (Beed blast) |  |

|

| Black Oxide |  |

|

Get Quote