Materials

Wide material options for your requirements

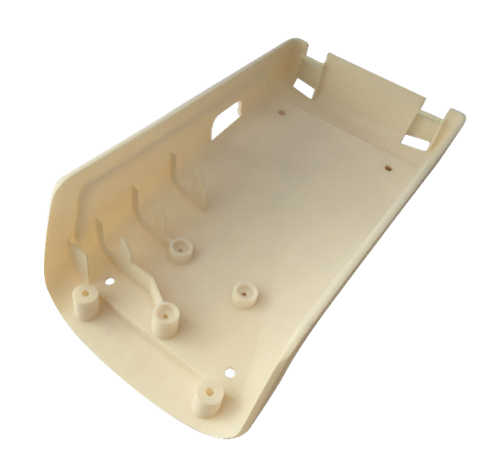

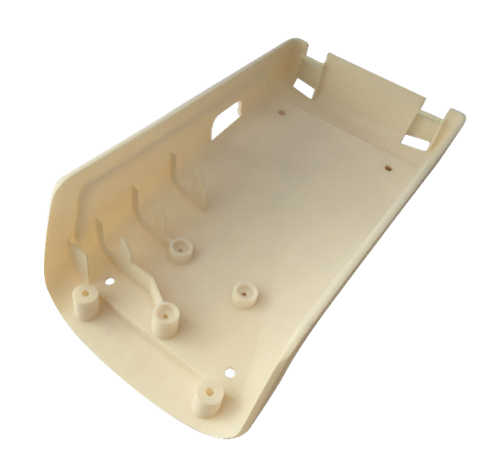

Vaccum Casting

ABS

ABS type thermoplastic where temperature resistance is required. Good chemical resistance. Good impact and flexural resistance.

ABS (PX223) Temperature resistance up to 110°C.

ABS High temp (PR700) Temperature resistance up to 130°C.

Color - Black

General Characteristics -

- Lightweight

- Fatigue resistance

- Greater tensile strength

- Excellent chemical resistance

Common Applications -

- Machine parts

- Pipes & fittings

Material properties -

| Grade | ABS (PX223) | ABS HT (PR700) |

| Modulus of elasticity / Young Mod. | 2.3 GPa | 1.8 GPa |

| Ultimate Tensile strength | 60 MPa | 60 MPa |

| Elongation at break | 11% | 13% |

| Flexural Strength | 80 MPa | 80 MPa |

| Impact strength | > 60 KJ/m2 | > 60 KJ/m2 |

| Hardness | 80 Shore D | 82 Shore D1 |

| Heat Deflection Temp. (HDT) | 110˚C | 130˚C |

| Glass Transition Temp. (TG) | >120˚C | >130˚C |

Post-processing -

- Painting

Other information -

| Price | TBD |

| Lead Time | 4~5Days |

| Max part size | 500x500x500mm |

Polypropylene

Polypropylene

Semi-rigid PP/HDPE-like for any need for the semi-flexible part with high impact resistance and mechanically demanding applications. Temperature resistance upto 90°C.

Color - Light brown

General Characteristics -

- Excellent abrasion resistance

- High rigidity and impact strength

Common Applications -

- Barrels

- Sealing

- Wastewater

- Spray carrier

- Acid industry

- Emission equipment

- Automotive industry

- Corrosion-resistant tank

- Drinking pipe accessories

Material properties -

| Grade | PR777 |

| Modulus of elasticity / Young Mod. | 1 GPa |

| Ultimate Tensile strength | 32 MPa |

| Elongation at break | 35% |

| Flexural Strength | 35 MPa |

| Impact strength | > 60 KJ/m2 |

| Hardness | 75 Shore D1 |

| Heat Deflection Temp. (HDT) | 90˚C |

| Glass Transition Temp. (TG) | >120˚C |

Post-processing -

- Painting

Other information -

| Price | TBD |

| Lead Time | 4~5Days |

| Max part size | 500x500x500mm |

Nylon

Nylon

Nylon (VC3360) is a polyurethane vacuum casting resin designed to simulate thermoplastics such as Nylon and glass-filled Nylon. It has a high flexural modulus, excellent physical properties.

Color - Light brown

General Characteristics -

- High flexural modulus

- Excellent physical properties

- High heat resistance and extremely rigid

Common Applications -

- Automotive

- Electrical & electronics

Material properties -

| Ultimate Tensile strength | 80 - 85 MPa |

| Elongation at break | 10 - 12% |

| Hardness | 85 - 90 Shore D |

| Heat Deflection Temp. (HDT) | - |

| Glass Transition Temp. (TG) | 82 - 87˚C |

Post-processing -

- Painting

Other information -

| Price | TBD |

| Lead Time | 4~5Days |

| Max part size | 500x500x500mm |

Polycarbonate

Polycarbonate

Polycarbonate is suitable for optical piece prototyping. Very high UV stability. Easy to polish and to color.

Polycarbonate PRC1710. Temperature resistance upto 93°C.

Polycarbonate high temp PRC1708. Temperature resistance upto 105°C.

Color - Transparent

General Characteristics -

- Strong

- Good optical clarity

- High impact resistance

- Stiff and outstanding toughness

Common Applications -

- Skylights

- Optical materials

- Lighting materials

- Architectural glazing

- Impact strength parts

- Transparent manifolds

- Semiconductor machinery components

Material properties -

| Grade | PC (PRC1710) | PC HT (PRC1708) |

| Color | Transparent | Transparent |

| Modulus of elasticity / Young Mod. | 2.4 GPa | 2.3 GPa |

| Ultimate Tensile strength | 65 MPa | 70 MPa |

| Elongation at break | 15% | 16% |

| Flexural Strength | 84 MPa | 80 MPa |

| Impact strength | 48 KJ/m2 | 90 KJ/m2 |

| Hardness | 87 Shore D1 | 87 Shore D1 |

| Heat Deflection Temp. (HDT) | 93˚C | 105˚C |

| Glass Transition Temp. (TG) | 100˚C | 110˚C |

Post-processing -

- Painting

Other information -

| Price | TBD |

| Lead Time | 4~5Days |

| Max part size | 500x500x500mm |

EPDM

EPDM

EPDM VC 3300 is a flexible, polyurethane material. By altering the ratio of the formulation, the hardness of the cured rubber can be selected. Very soft elastomers of 35 (Shore A) through tough, semi-flexible elastomers of 95 (Shore A) can be achieved.

Color - Black

General Characteristics -

- Flexible

- Variable hardness could be achieved

Common Applications -

- Electrical encapsulation

- Rapid prototyping

- Model making

Material properties -

| EPDM 3300 (Black Color) | ||||||||

| Properties | Unit | Result | ||||||

| Hardness | Shore A | 35 | 45 | 55 | 65 | 75 | 85 | 95 |

| Tensile Strength | MPa | 1.5 – 3.5 | 3.0 – 5.0 | 4.0 – 6.0 | 6.0 – 8.0 | 7.5 – 9.5 | 9.5 – 11.5 | 9.5 – 11.5 |

| Elongation at Break |

% | 900 – 1100 | 1100 – 1300 | 700 – 800 | 500 – 600 | 400 – 500 | 300 – 400 | 200 – 300 |

| Tear Strength | KN/m | 7 - 11 | 13 - 17 | 17 - 23 | 22 - 28 | 36 - 42 | 55 - 61 | 74 - 80 |

| Max Operating Temp. | ˚C | 60 | 60 | 60 | 60 | 80 | 80 | 80 |

Post-processing -

- Painting

Other information -

| Price | TBD |

| Lead Time | 4~5Days |

| Max part size | 500x500x500mm |

3D SculpLab

3D SculpLab