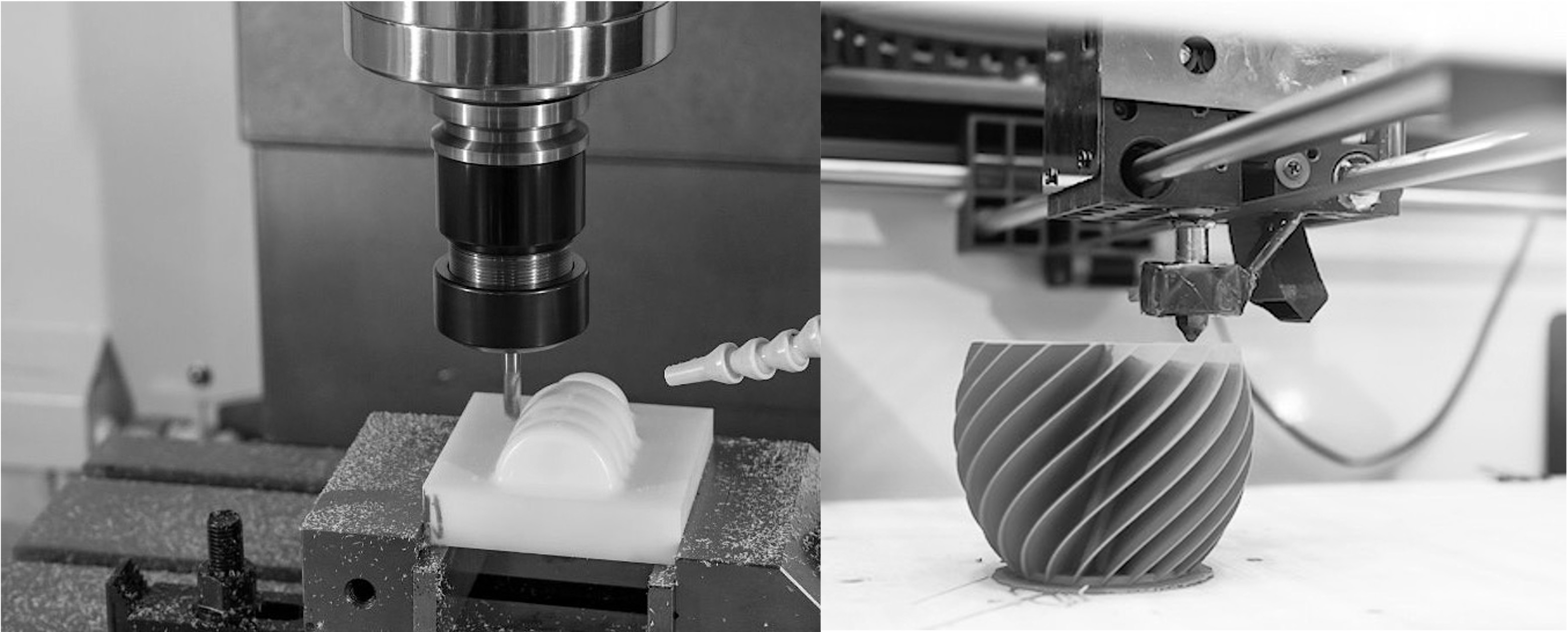

To develop prototypes, short-run production parts, CNC & injection molding were the conventional technologies available to designers. Designers would create a geometry/drawing and send it to the fabricator to discuss the specifications, costs and delivery time. Usually, the lead times are long, and designers had to wait patiently to get their hands on the parts. With multiple iterations, it takes several months before the design gets off the design and validation table to go into serial production. In the worst-case scenario, the product may become obsolete by the time product reaches the mass production stage. P

With the advent of additive manufacturing and its mainstreaming, the development of prototypes has been accelerated from several weeks to a few days or hours. Designers can quickly iterate and mature the product before hitting the market. But that doesn’t mean conventional manufacturing processes (CNC, injection molding) have lost their relevance. CNC can create parts where close dimensional tolerances are the key to the performance of the design. Hence, it's up to the designer to select which manufacturing technology is most suitable for development.

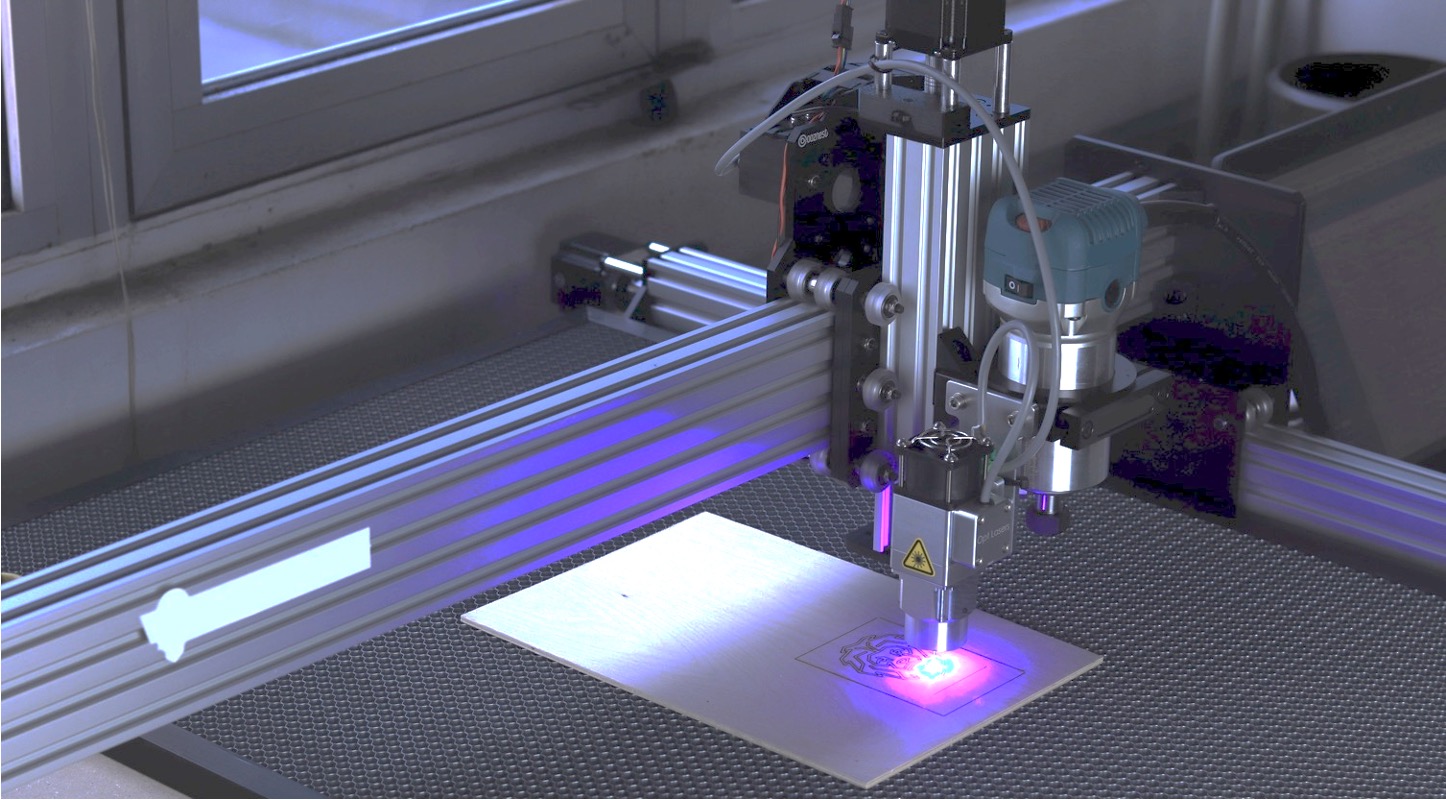

Application

Product application is the key factor which decides the material selection and manufacturing technology. For demanding applications where a high degree of reliability is the key, the part is machined to the closer tolerances subject to process, machine, and material limitations. For application where frequent changing of parts are required, then additive manufacturing is the most suitable technology. In some applications, metal parts (for example aluminum) can be substituted by AM made composite material parts which are lighter in weight and faster to produce and costs less. Also, AM can quickly produce parts which are out of regular production saving time and money.

Material type

Most of the plastic parts are easy to machine and have no issues during the machining process. It's up to the designer to select the material according to the application. ABS, PP, nylon, Delrin, acrylic, PEEK, Teflon, and polycarbonate are some of the engineering-grade plastics available. Certain glass-filled materials are also available but are somewhat difficult to machine. Teflon is slippery in nature and acrylic can get fragmented during machining. Machined plastics are as good as any other plastic parts produced by injection molding or vacuum casting and can be used for any application. Plastics are more elastic in nature than metal and have 10 times more thermal expansion coefficient. Their softening temperature is much lower than metals. During machining localized heating needs to be avoided because plastics dissipate heat more slowly than metals.

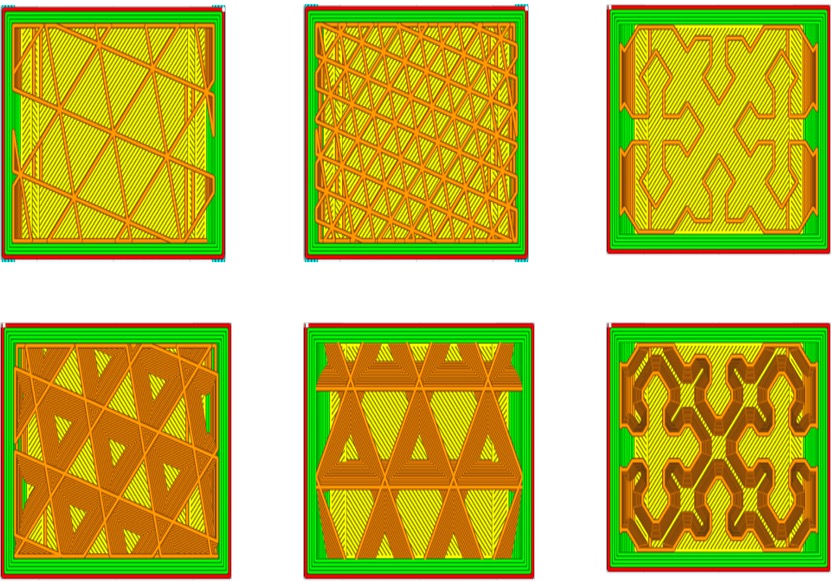

On the other hand, there are limited numbers of plastic materials available per AM process. Most of them are available in FDM/FFF additive manufacturing like PLA, ABS, PP, PC, Nylon, Co-polyester, TPU, composites etc. For SLA, there are resins which exhibit properties of PP, ABS, PC and flexible etc. For SLS, nylon is the only material. Limited machining can be done on plastic AM parts for features like holes to bring their dimensions within requirements.

Design geometry

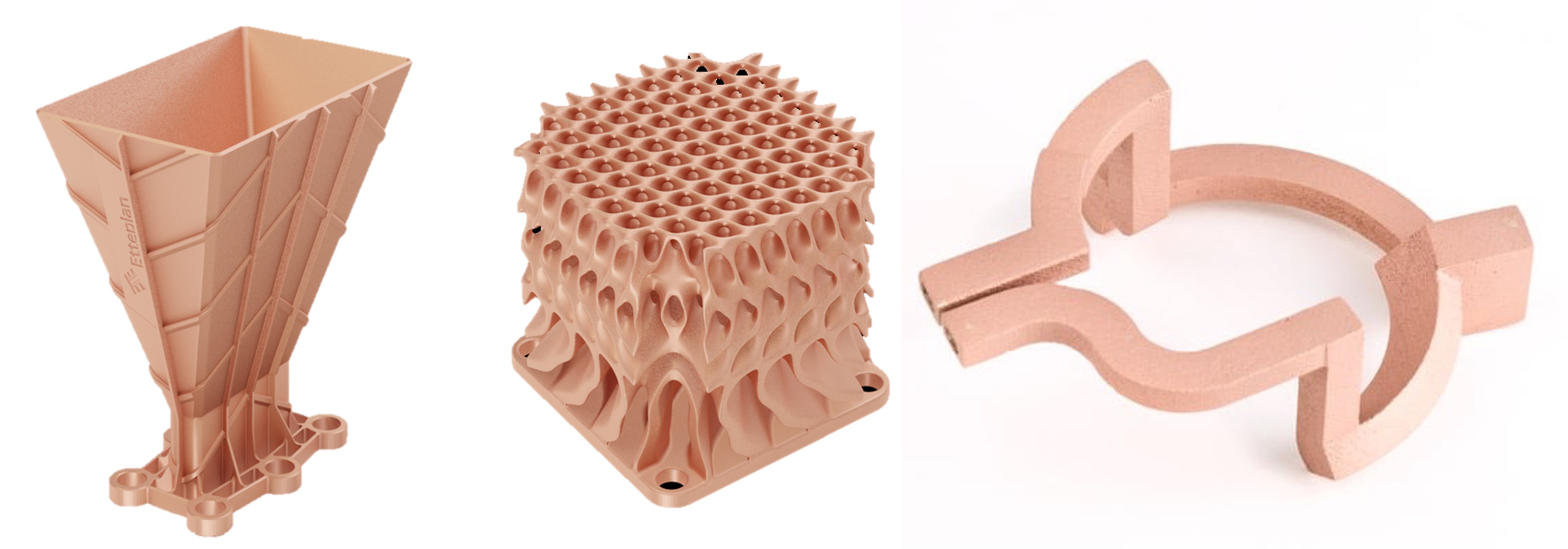

For simpler and less complex designs, it is recommended to go for CNC machining because it costs less. For example, a mounting bracket of an automobile, holdings or spacers for delicate items like glass, fixtures for plastic items or delicate machine components. Multiple operations can be done at the same time on CNC and the finished part is ready for application with some minor post-processing. However, CNC has its limitations like it is difficult to make deep undercuts and deep internal geometries. There are no such limitations for additive manufacturing and can create complex geometries with ease and cost-effectively. AM can create geometries which are entirely not possible by any conventional manufacturing process like CNC, injection molding and vacuum casting. Conformal cooling channels of the core of a mold can only be made by AM. Designs which can be made by machining can also be made by injection molding for mass production. On the other side, AM produced geometries can only be made by AM or the design needs to be modified to match injection molding requirements.

3D printed complex geometry. Photo credits: nTopology

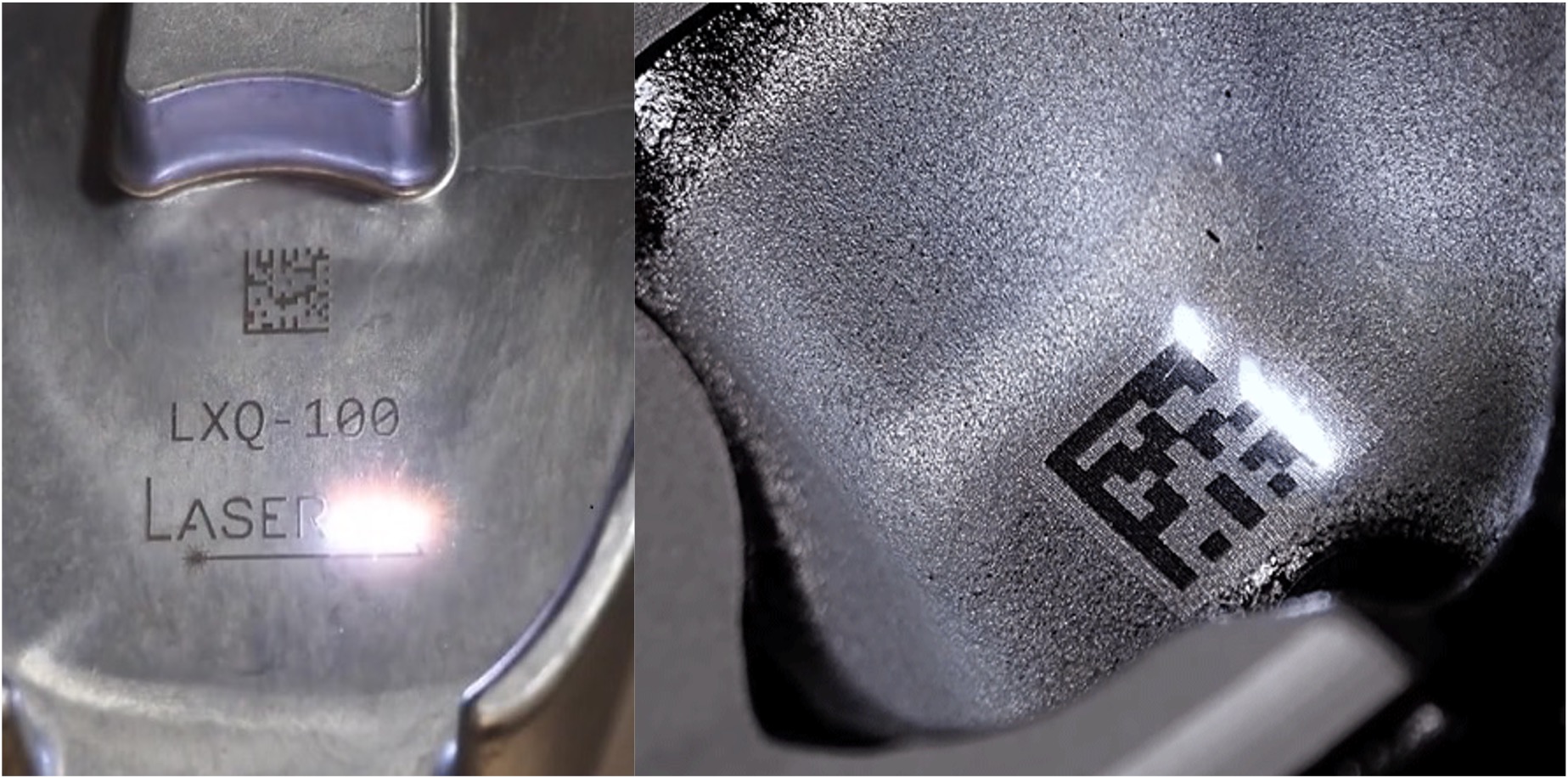

Finish

Machined parts have better accuracy and surface finish than AM produced parts. SLA 3D printed parts are somewhat closer to the machined part in terms of finish and accuracy. Machined parts have a smooth surface with some shiny finish depending upon the material. The finish can be further enhanced by polishing and painting. AM parts have a rough finish and, in some cases, need extensive post-processing to achieve desired finish quality. SLA parts have a better surface finish than other AM process but still needs some processing to enhance surface quality.

Tolerance

No doubt machining achieves higher dimensional/profile tolerance than additive manufacturing. However, the best machining tolerance moves around 200 microns due to process limitations and it is slightly more in the case of nylon. Plastics are machined at a slower speed than metal due to the low melting temperature of plastics. Higher speeds may cause deformation due to high heat generation. Tolerances of AM made parts are much lower than machined parts due to process limitations. For FDM parts, it is 250 microns for smaller parts to 0.5~1mm or more for larger parts. SLA 3D printing gives better dimensional tolerance which from 150 to 100 microns.

CNC machined plastic component

Conclusion

CNC and additive manufacturing supplement each other. In the case of multipart assembly products, a designer can choose to make less complex designs by CNC and complex geometries by additive manufacturing leveraging the advantages of both processes. Plastic prototyping either by machining or 3D printing is always in demand and which process is best to manufacture depends upon factors like application, material and geometry. Plastic is an ideal low-cost alternative to metal prototyping when the intent is to verify the fit and form of any design before making it in metal, hence saving time and money. With the rise of additive manufacturing, there’s no threat to CNC due to the inherent benefits offered by the machining process when comes to finish and tolerances. Instead, a fusion of CNC and AM is the way forward in the near future.

Blog created by - 3D SculpLab Team

3D SculpLab

3D SculpLab